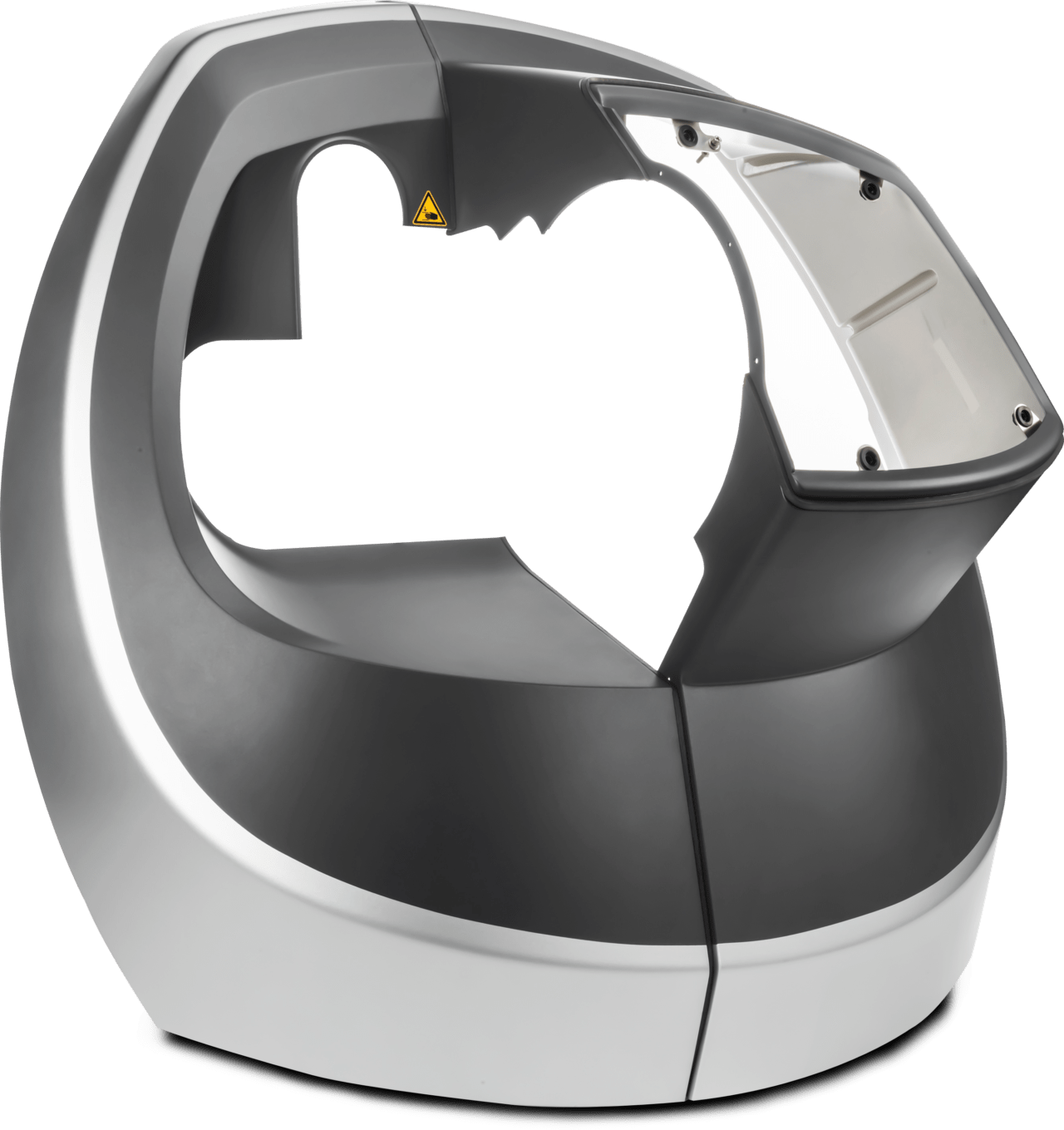

ARTIS pheno

Complete cover of a robot

Project scope

Development, prototyping and series production of the entire cover assembly of the ARTIS pheno robot system incl. the mechanical subassembly.

Requirements

- High mechanical stresses

- Chem. resistance against cleaning agents

- Biocompatibility

- Anti-microbial surfaces

- Fire protection in accordance with UL 94 V-0

- Three-colour coating plus screen printing

- Substructures and covers must outlast kinematics and dynamic movements of the robot in the long-term

Highlights of the project

Mechanical requirements and design

The in-house development department of Hombach developed and constructed the complete substructure for connecting more than 12 cover assemblies.

The design expectations were realised equally as sophisticated with three adjacent colour coatings in different surface structures incl. screen printing.

Range of services

Development and construction of various subassemblies made of stainless steel and aluminium and consideration of the dynamic movement and kinematics of the robot.

Development and construction of all cover parts, connection components and seals in various production technologies (Twin-Sheet, GFK, pressure die-casting, injection moulding, PU flexible foam as well as laser/edge, pressure-die casting turned parts and various extrusion profiles).

1:1 prototyping of the entire assembly for shoring and collision tests.

Series production incl. sourcing of all components and component assembly for delivery of the complete cover.

All components are coated in-house with an anti-microbial textured paint. Some matt and high-gloss accent colours are painted, and labels and logos are added through screen printing.

All products and parts in our showroom represent a small part of our implemented projects. We will be pleased to check your projects for feasibility and economic efficiency free of charge at any time, or we can provide you with recommendations for suitable technologies.

(c) PLEASE NOTE that all images shown here are subject to the copyright of Ernst Hombach GmbH & Co. KG, of our customers or commissioned photographer. Photos must only be used for other publications, marketing campaigns or similar with written approval.